Basics of Birefringence Measurement(1/4)

Four articles explain the understanding of birefringence and the measurement principles and features of our equipment.

1.Basics of Birefringence Measurement

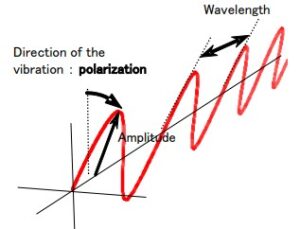

The three components of light

①Amplitude = brightness

![]()

②Wavelength = color

![]()

③Direction of the Vibration: polarization

In contrast to amplitude and wavelength, polarization cannot be recognized by the human eye,

making it difficult to apprehend intuitively.

Basic Principle of Polarization Measurement

Rotating a polarizer and observe the change of intensity transmitted through the polarizer.

when Input Direction = Polarizer Direction → 100% transmitted

when Input Direction ⊥ Polarizer Direction → 0% transmitted

when 45deg. … → 50% transmitted

Polarization and Birefringence

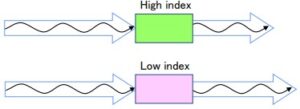

Refractive index = how easily light passes through the material

The higher the refractive index is, the more time is needed for light to pass through the material.

※Optical length=Refractive Index x Length

Example: for glass with index n = 1.5, light is slowed down by a factor 1.5.

Birefringence = when refractive index depends on light polarization

| Material | Ordinary | Extraordinary | Birefringence(⊿n) |

|---|---|---|---|

| Calcite | 1.6584 | 1.4864 | 0.172 |

| Quartz | 1.5443 | 1.5534 | 0.0091 |

| Sapphire | 1.768 | 1.76 | 0.008 |

| Ice | 1.309 | 1.313 | 0.004 |

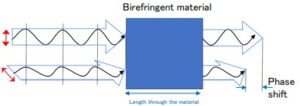

Phase shift = Birefringence × Length

Here, we assume that different polarizations are passing through the material at the same point.

Thus, length is the same ⇒ Phase Shift ∝ Birefringence

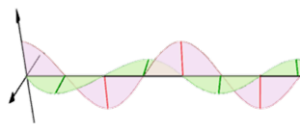

Impact of Birefringence on Light Polarization

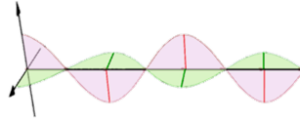

Phase Shift between Each Polarization Component and Total Polarization Resulting.

every state of polarization existing is the result of a combination of 2 perpendicular components.

①In Phase

Linear Polarization

②Quadrature

Circular Polarization

※ Depending on the phase shift between the 2 components, a different state of polarization results.

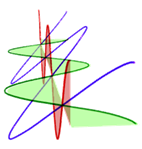

Material exhibiting birefringence makes polarization change

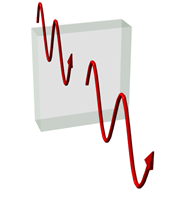

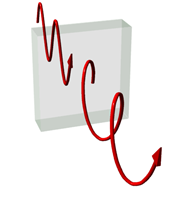

【 non-birefringent material】

No change in polarization Crossed polarizers (cross Nichols): dark, no light is detected.

【birefringent material】

Change of polarization Even with crossed polarizers, light is detected due to the change of polarization induced by the birefringent material.

Crossed polarizers completely shut down the light trying to go through

↓

A non birefringent material placed between does not change the situation

↓

A birefringent material placed between the crossed polarizer appears bright

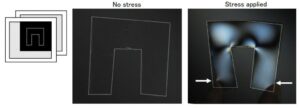

Birefringence caused by stress

Even in non birefringent materials, internal stress can induce birefringent behavior.

This phenomenon, called “photo-elasticity,” imply that observed birefringence is proportional to the stress applied to the material. The proportionality constant, referred to as the “photo-elasticity constant,” is a property of each material.

birefringence= β×stress [force] (1012Pa)

phase shift δ(nm) = β×thickness d (cm)×stress [force] (105 Pa)

~β is the photo-elastic constant for the particular material [ 1012/Pa ]

For example,

a force of 1MPa applied to a 1mm quartz plate results in a phase shift of:

3.5×0.1×10=3.5nm

| Material | Photo-elastic constant(10-12/Pa) |

|---|---|

| Quartz | 3.5 |

| Polycarbonate | 75 |

| Acrylic | 6 |

| Glass | 0.5 |

| Lead glass | 0.005 |

※Natural birefringence of rock crystal quartz is approx.0.01(1.55-1.54). The amount of force to obtain this value by photo-elasticity is 0.003TPa=3GPa, which is very big. Generally, birefringence exhibited by the photo-elastic effect is much smaller than in naturally birefringent quartz.

※The major part of the birefringence observed in a plastic molded object is thought to originate from molecular orientation rather than from photo-elasticity. Thus, for this type of object, it is not reasonable to calculate the amount of stress from the birefringence observed. However, differences of birefringence still can be linked to differences of the molding process, thought as a whole. That is why birefringence analysis is a good evaluation technique for plastic molding process.

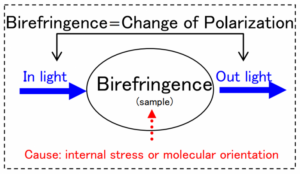

Summary: Polarization, Birefringence, Phase Shift, Photo-elasticity

Evaluating the distribution of birefringence enables the access to information about internal stress and molecular orientation in transparent materials.

Birefringence in material modifies the polarization of the light going through.

↓

Thus, comparing light polarization in and out allows for measuring birefringence in the material.

↓

Birefringence Measurement =Polarization Measurement + Difference Computation.

※A birefringence measurement system must be, as long as we talk about hardware, a polarization measuring device.

Computation Flow

①Polarization Measurement

↓

②Phase Shift Computation (from change of polarization)

↓

③Birefringence Computation (from phase shift and sample thickness)

↓

④ Internal Stress Computation (from birefringence and photo-elastic constant)

Theoretically, computation of birefringence and internal stress is possible. However, because of the following

reasons birefringence measurement device usually provide data

for ② phase-shift only:

a. sample geometry data is not easy to manipulate in a universal manner

b. phase-shift data is often more relevant than birefringence for most applications

c. the cause of birefringence is rarely internal stress only, but a combination of factors

The user is then free to keep further the computations based on its own knowledge about his sample geometry and material.

Continue to the next page

Category

- #Birefringence & stress strain measurement solutions

- #2-D Birefringence Measurement System

- #Birefringence Measurement System