Feature

The world’s fastest polarized high-speed camera to visualize the “internal stress” and “orientation structure” of transparent materials

- Analysis and visualization of internal stress distribution during material processing

- Evaluation of stress propagation around cracks due to impact fracture and cracks

- Dynamic observation of crystal axis/orientation state on liquid crystal/crystal materials

- Visualization of fluid stress distribution generated by viscoelastic body or soft matter

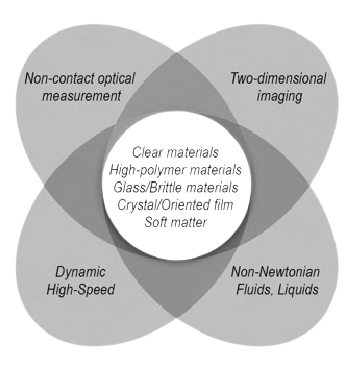

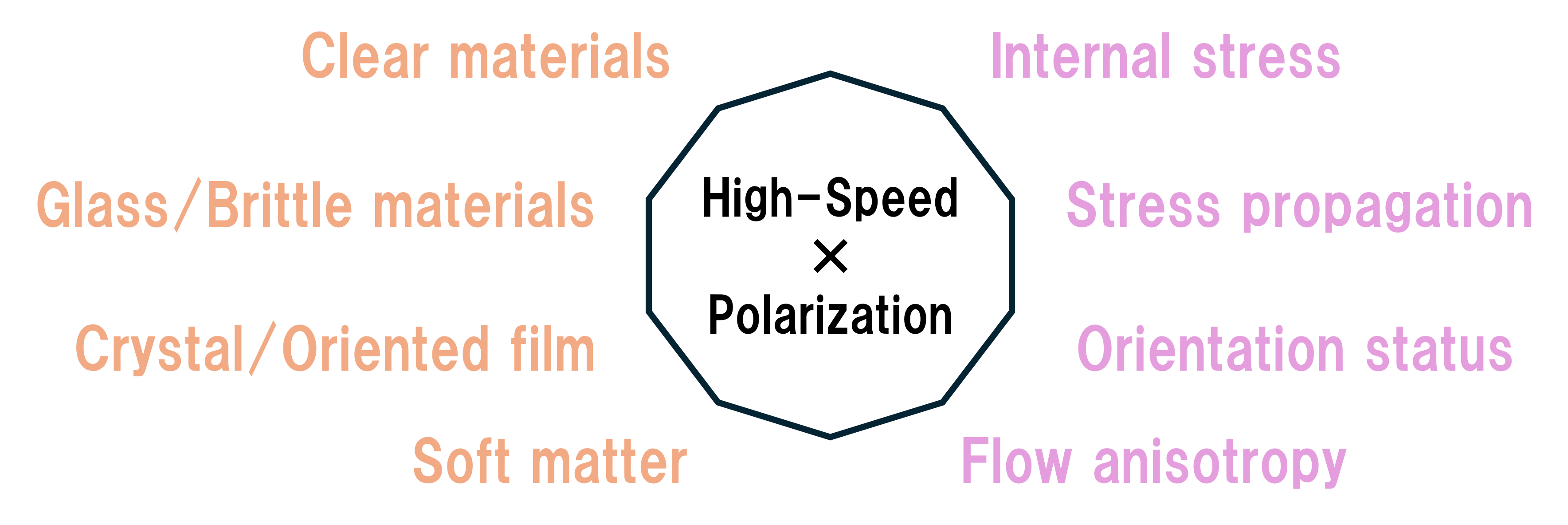

Polarization can measure and visualize various physical quantities and physical properties.

Polarization is “light that vibrates in regular direction” and it cannot be recognized by human eyes.Since the polarization state varies depending on the internal structure of the transmitted object and the surface shape of the reflected object, it is recognized that it can be applied to the measurement of various physical quantities and the visualization of phenomena by measuring the polarization state of the incident light and the transmitted light to/from the object.

Furthermore, the combination of “Polarization” and “High-speed imaging” technology will enable new image analyses that were previously unimaginable, such as examining the load applied to tools during the processing of transparent materials from images, visualizing stress propagation and relaxation processes in impact tests and flow phenomena, and quantitatively measuring the spatial performance uniformity of alignment films in a non-contact manner.

Unique core technology

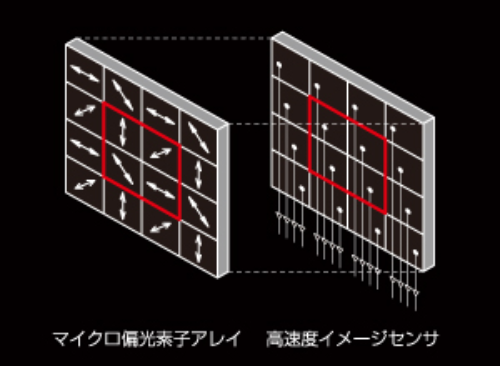

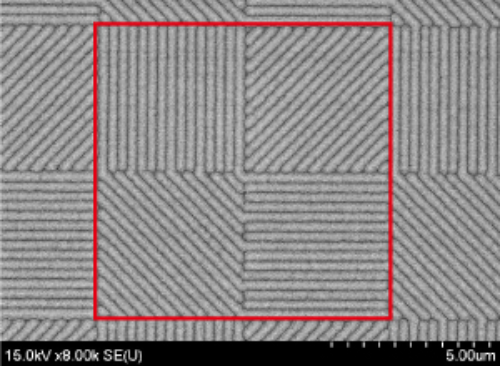

Polarization high-speed image sensor

An image sensor jointly developed by Photron Ltd. and Photonic Lattice with photonic crystal micro-polarizing element array which implements different orientation for each pixels. It eliminates the need for the rotational operation of the polarizing plate, which has been indispensable for polarization measurement, and has the feature of being able to acquire the light intensity information required for polarization measurement with a single exposure. Additionally, it’s a completely new image sensor that has improved the repetitive sampling speed by 1000 times or more compared to the conventional one by directly connecting the original pixel parallel readout circuit and the polarizing element.

Whole new evaluation index for R&D of transparent materials and molded products

CRYSTA can measure the distribution of “retardation (nm)” and “principal axis(°)” of transparent materials and complex fluids such as resin and glass.The retardation value is determined by the strength and orientation of the stress inside the material, and the principal axis is the direction in which the moreclular structure is oriented (Orientation angle).

It can also be used as a monochrome high-speed camera, which is a new evaluation technology in various R&D fields.

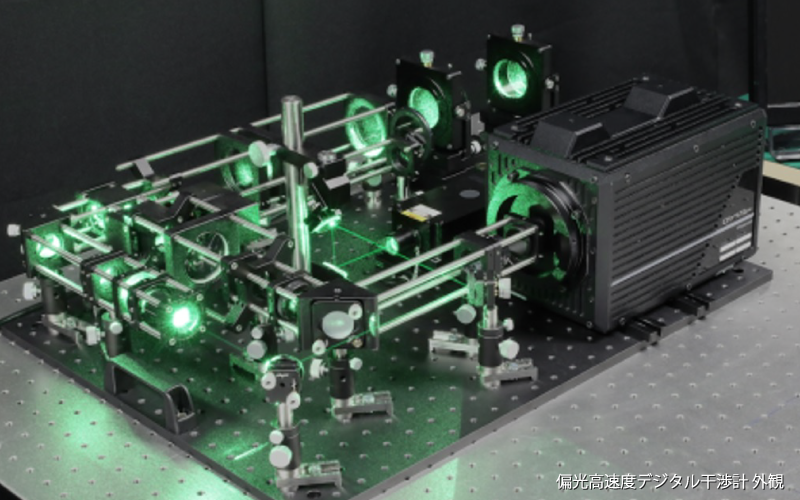

Development of High-Speed Polarized Interferometer based on CRYSTA series

Unique interference system sustained by our original “CRYSTA Phase Optics”. The product includes software: “CRYSTA phase viewer” for system operation and “CRYSTA Phase Analysis” for advanced analysis of interference fringes. Its high-speed real-time capabilities allow the evaluation of fast-moving dynamic phenomena.