Birefringence unevenness film inspection

KAMAKIRI 2D Birefringence Phase Difference Mapping System for Quick Detection of Defects and Preventing Outflow of Defective Products

Evaluation and inspection of optical distortion and uneven orientation in performed on transparent optical films (PVA, COC, COP, TAC, PC, PET, PMMA, PI).

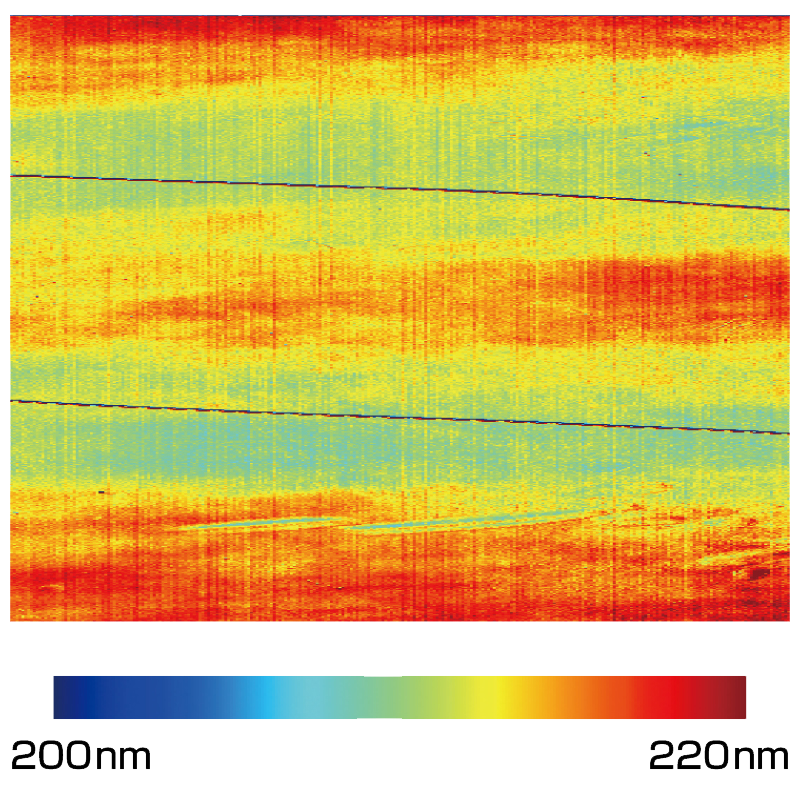

Horizontal unevenness

In high-definition displays, unevenness patterns of a size of a few millimeters are attracting attention. Among them, transversal unevenness patterns are caused by contact failure with chiller rolls, gear marks on conveyor equipment, vibration, and other factors. The system can detect this type of unevenness, among other types, having a width spanning from a few millimeters to several tens of millimeters.

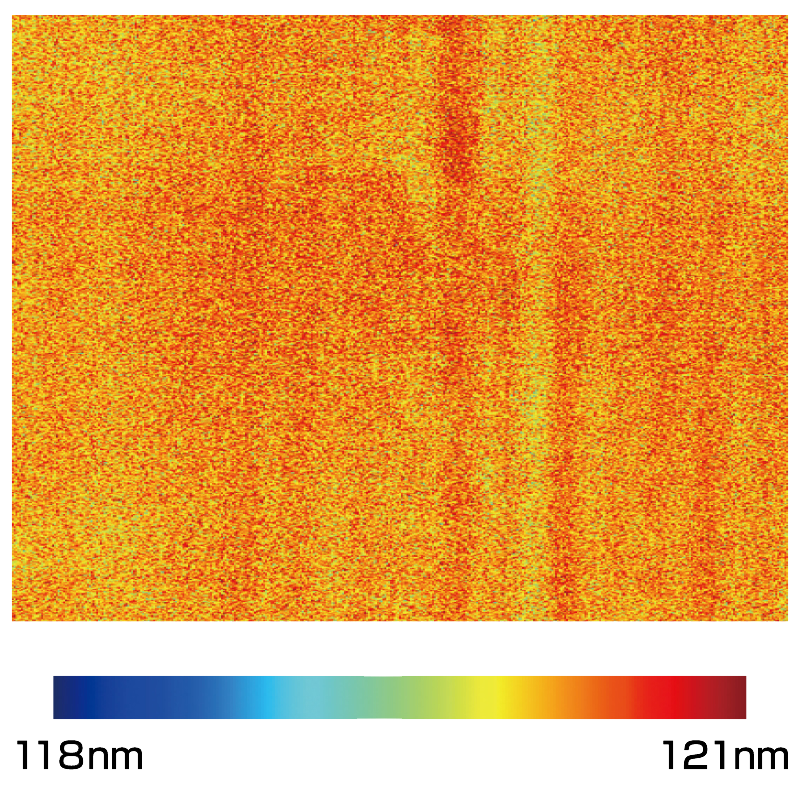

MD stripes

MD stripes are caused by debris adhering to the die lip. In addition, these MD stripes are accentuated during the stretching process. MD stripes are difficult to quantify by visual sensory testing, but it can be visualized and quantified.

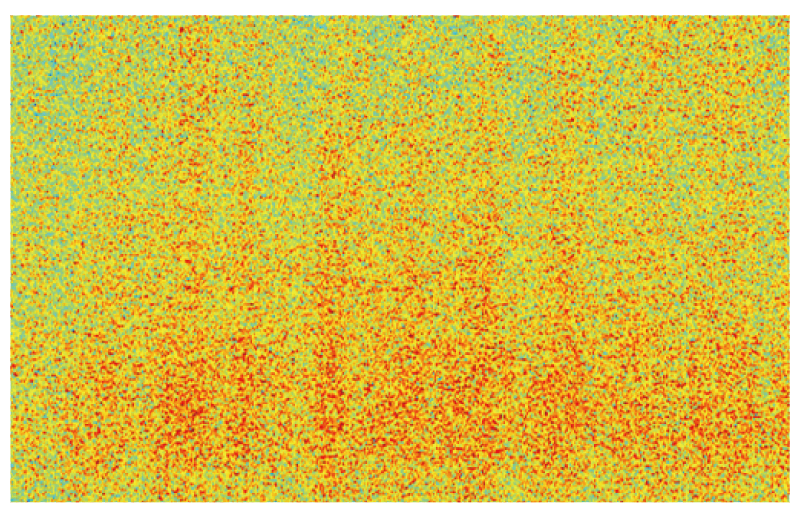

Unevenly spotted

Dust adhering to the rolls causes periodic or sporadic spot-like unevenness in the film. This is one of the defects that can easily be missed by conventional spot inspection. By measuring the entire surface, the system detects all unevenness event occurring at random location without missing any.

Ultra-low phase difference base material + birefringent material film

In films obtained by coating on glass substrate or OLEO-type optical film, birefringence unevenness occurs during the coating and drying processes. Because of the very fine streak structure of unevenness, conventional spot measurement tends to miss them while direct visual inspection make difficult to precisely determine the location of the defects. Desktop-type KAMAKIRI can visualize streak unevenness, and can classify the level of streak unevenness based on the difference in phase difference between the peaks and valleys.

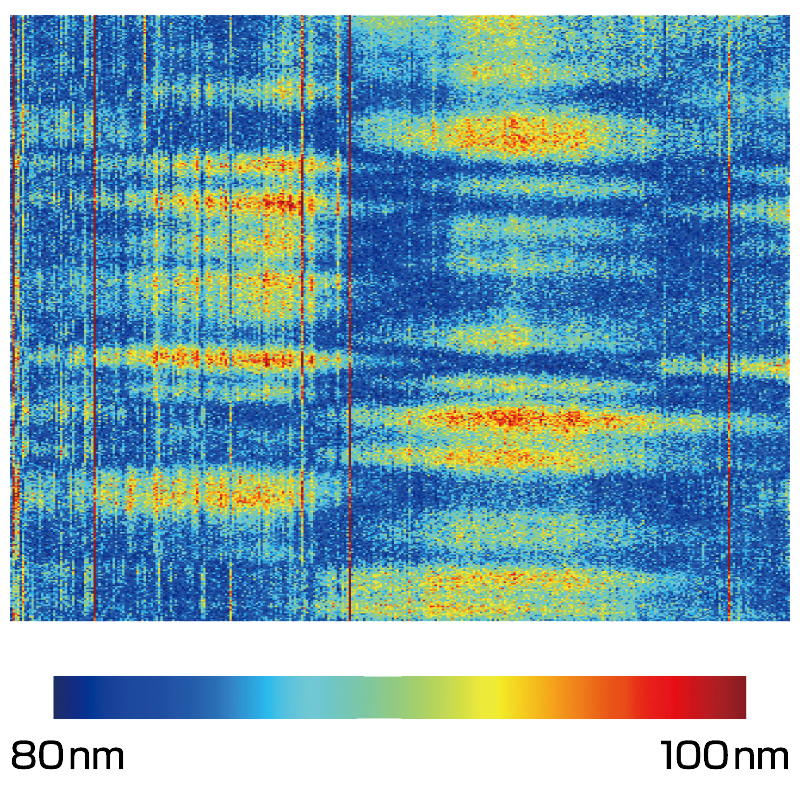

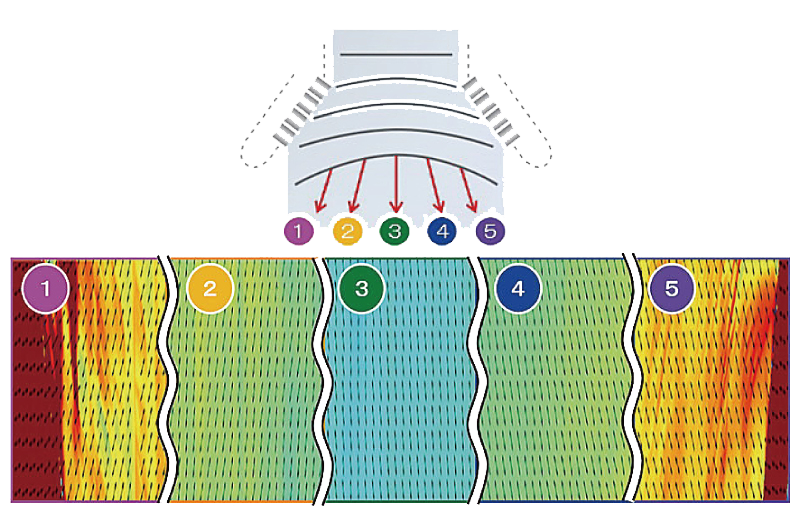

Bowing Phenomenon and Orientation Control

Bowing phenomenon occurs during the biaxial stretching process of a film, where the center of the film in the TD direction shows delayed or prior deformation compared to the edges.

Therefore, a system that can easily evaluate film performance in the TD direction has been desired. The inline type KAMAKIRI displays real-time the bowing phenomenon on site, eliminating the time required for sampling inspections and allowing for quick adjustment of production parameters.

related product

Category

- #Full-length, full-width film quality control solutions

- #In-line/off-line mapping-type birefringence measurement system

- #Birefringence Measurement System