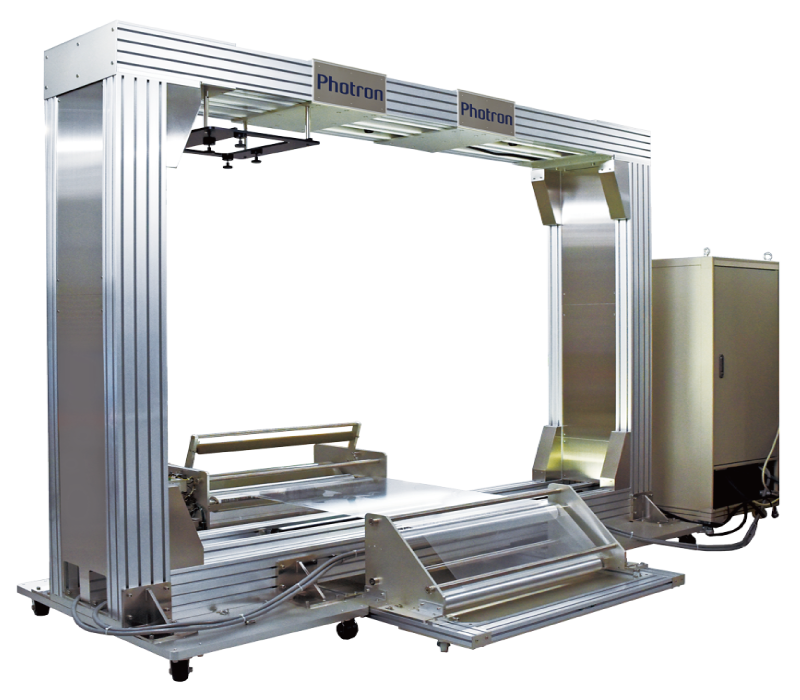

In-line/off-line mapping-type birefringence measurement system

KAMAKIRI STS-LS

For in-line quality and production control

Full-width and full-length inspection for irregularities that cannot be visually detected

KAMAKIRI STS-LS is the only system capable of inspecting the entire surface of films produced continuously for a long period of time. It supports a live display function to check results on the site and an pass/fail judgment function, to enable early detection of defects.

Feature

01

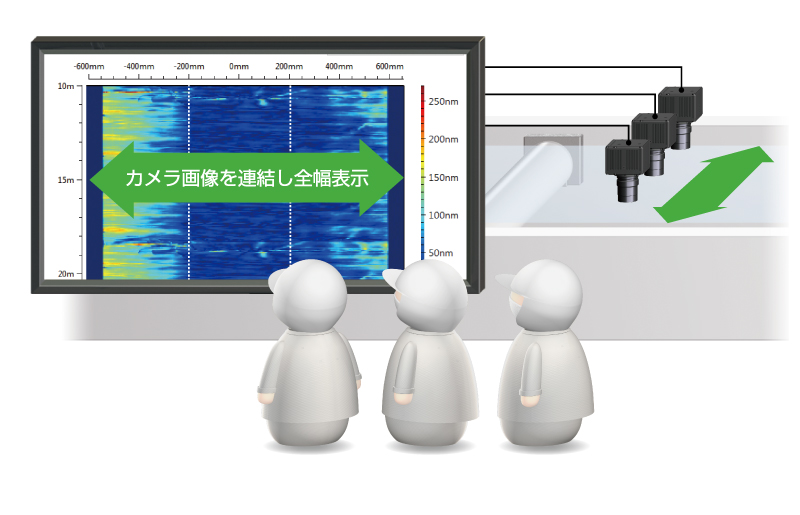

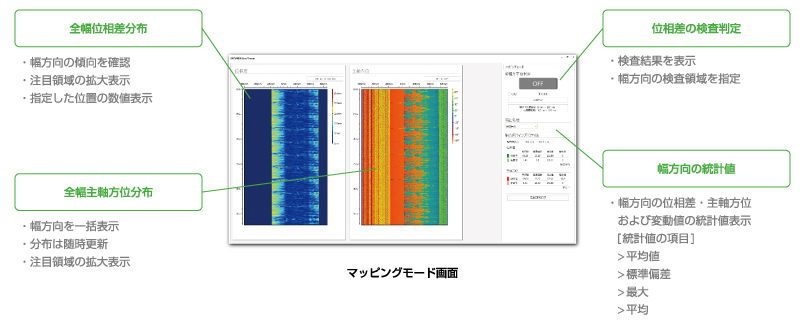

In-line full area inspection

& defect detection

Connect multiple cameras according to the width of the film. The monitor screen displays the measurement results of all cameras at once in real time, therefore defective area can be immediately confirmed.

02

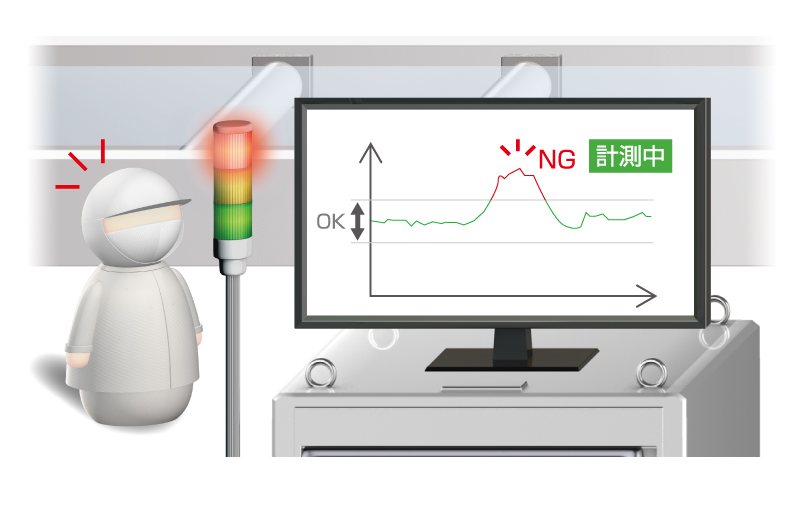

Inspection of retardation

If a retardation defect is detected, a warning light or screen will immediately alert the person in charge of the site.

03

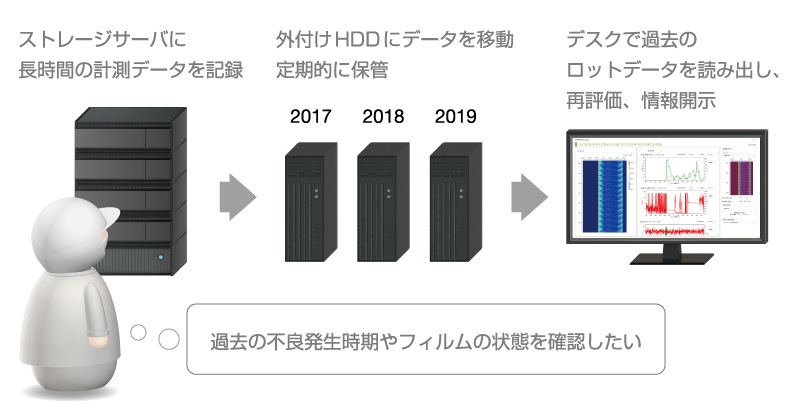

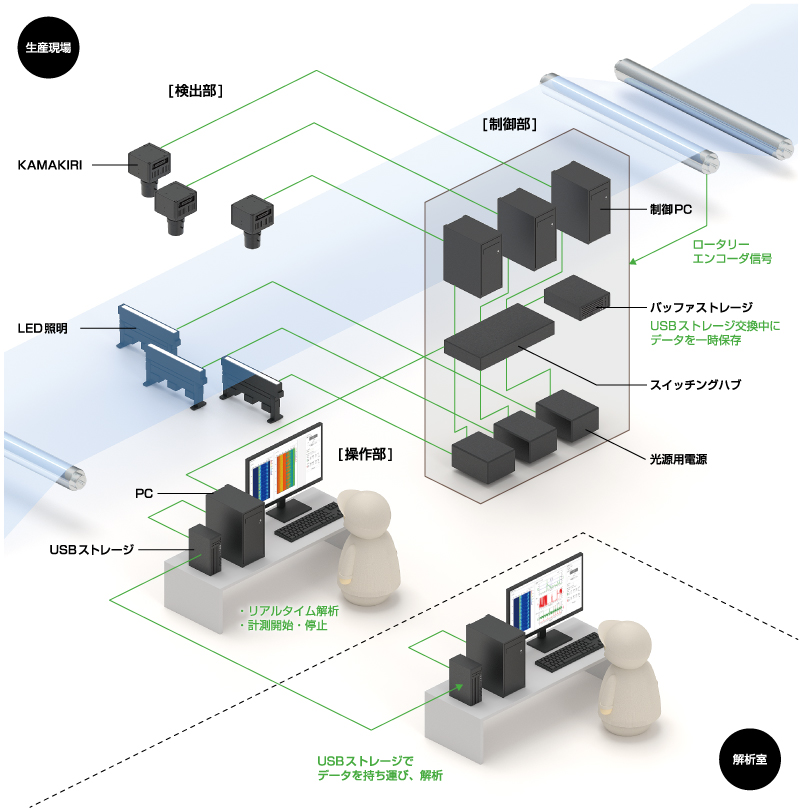

Long time recording

Once production begins, constant inspection is required. The large amount of data generated during such continuous inspections is managed in storage. Buffer storage prevents data from being lost even when recording capacity is insufficient, thus ensuring reliable operation.

04

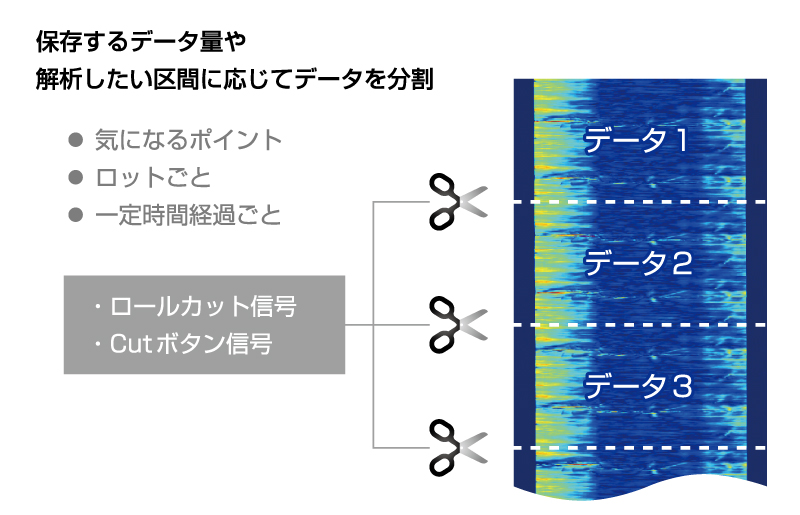

Auto data save by production lot

By inputting the film cutting signal into the system, data can be divided as the end of the production lot (beginning of the next lot) and data can be automatically saved by every production lot. The date and time are automatically recorded, making it easy to identify and review the data.

05

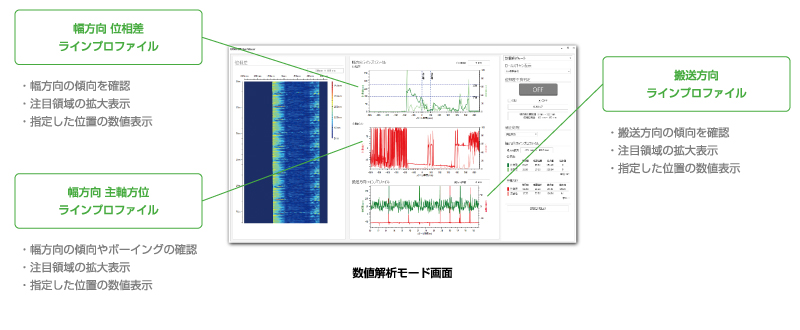

Live display useful on production line

Items that need to be known immediately on site, such as real-time display of optical strain and trend graphs (width direction and transfer direction) as in conventional inspection equipment, can be viewed on the monitor.

06

Data flow and operational image

We provide system operation and mechanisms suitable for your production line situation.

Spatial resolution and storage are determined according to the degree of irregularity to be detected and the production volume.

We will also manufacture an enclosure that can be installed based on the pass line and the space available in the factory.

If your research topic involves confidential information, we can conclude a Non-Disclosure Agreement (NDA). Please feel free to consult with us.

| Model name |

|

|---|---|

| Major application |

|

| System features |

|

| Measurement item |

|

| Retardation measurement range |

|

| Retardation repeatability |

|

| Principal axis orientation measurement range |

|

| Principal axis orientation repeatability |

|

| Center wavelength for measurement |

|

| Number of measurement points |

|

| Maximum measurement width at line scan |

|

| Supported transport speed |

|

| Software [Japanese/English] |

|

| Customization achievement |

|

Catalog & Company brochure Download

Category

- #Full-length, full-width film quality control solutions

- #In-line/off-line mapping-type birefringence measurement system

- #Birefringence Measurement System

- #Film