Birefringence unevenness inspection of transparent resin molded products

Inspection of transparent resin molded products

Our birefringence measurement products, like PA series, WPA series, including WPA-KAMAKIRI, are widely used for visualization and quantitative evaluation of residual stress distribution, which can cause cracking or degradation of optical performance such as MTF and transmittance degradation.

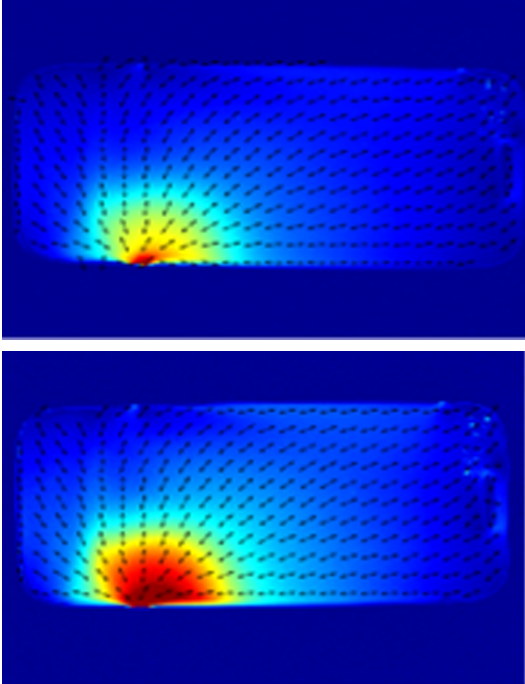

Internal Stress in Molded Product

Phase difference distribution sensitively reflects differences in molding conditions, making it ideal for process control. Good products (above) and defective products (below) can be compared and quantitatively judged as good or bad.

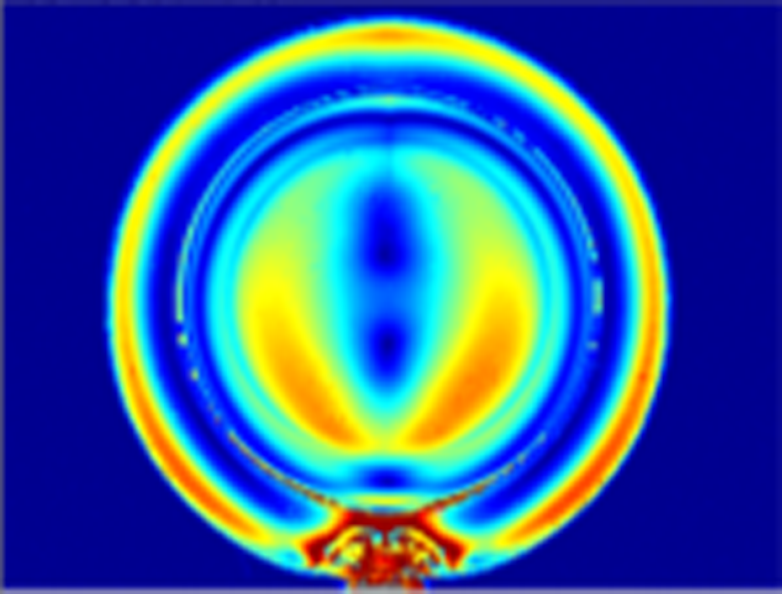

Visualization of resin flow

During plastic lens molding, when gate distortion extends to the effective diameter, resolving power of the final lens is degraded. Quantitative evaluation enables determination of low distortion molding conditions in a short period of time.

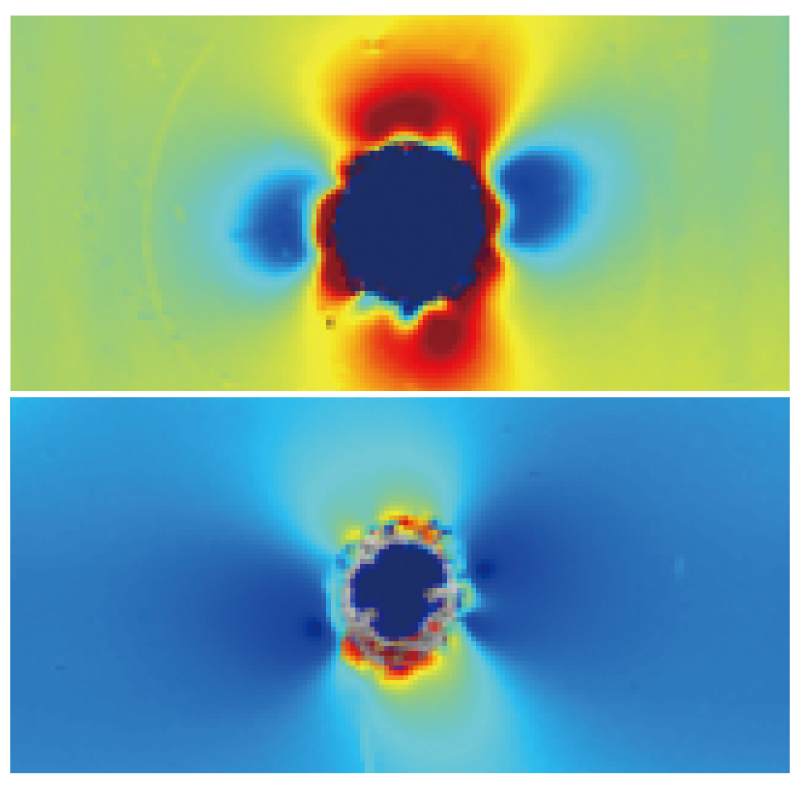

Quality control of processing

Defective drilling of molded products increases residual stress and causes cracks and other defects.

The inspection can be performed in a short time (approx. 1 minute) for quality control of residual stress after processing.

related product

Category

- #Birefringence & stress strain measurement solutions

- #2-D Birefringence Measurement System

- #Birefringence Measurement System